Predictive Quality for Manufacturing

Quality control is absolutely crucial to any business. It is important to monitor the quality of products being offered to gain satisfied customers and to avoid the high costs associated with defective products. Defective products result in material consequences (replacements and rejections etc) , financial consequences (warranty, delays, margin loss etc) and intangible consequences (loss of customers and dissatisfaction etc)

- A single, scalable solution that reduces the defective rates of products by 15%

- Automation of the quality control process

- Actionable insights on how to fix quality control issues

Challenge

Quality control is an integral part of any manufacturing business. Using quality control processes, the defective products are weeded out from the rest of the products. This needs to be done as early as a possible in the production line. Once faults have been identified and the product is stopped from reaching the market, it is important to find out the root cause that gave rise to the fault. This is called root cause analysis. Root cause analysis a long and lengthy processes since it requires interdisciplinary collaboration.

Fortunately, with the help of machine learning, not only defective parts can be detected but also the product data can be monitored throughout the manufacturing process to predict any quality faults in advance. With this approach, the concerned operations team can be alerted of any anticipated faults along with the root cause.

Our Solution

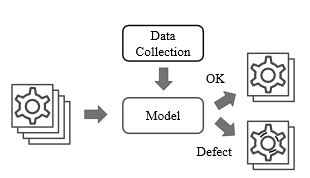

An AI based visual inspection system to automate the quality control process.

Quality control, though very crucial for the sustainability of a business is traditionally performed by a dedicated team of specialists. It is also an expensive process. We built an AI based end to end system to automatically detect flaws in the products. Apart from detection, the system also has the ability to classify each defect. Instead of using a hard coded list of defects with an algorithm, the system itself “learns” different types of defects from the products. Very efficient image recognition and deep learning models have been used for the development of the system.

Technical Bit

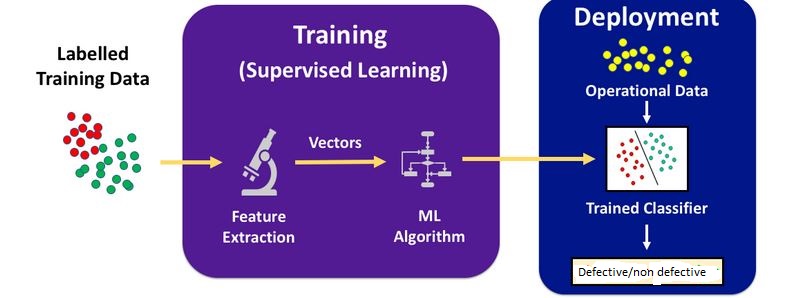

Just like any other machine learning based system, the first step is to gather data and then label it. There are two core functions of the system. The vision part which is concerned with classification of defective and non defective products. For this system, we collected thousand of images for training our model. The second function is the predictive quality in which faults are predicted in the product during the different stages of manufacturing process. For this, we collected 1000 different product features at different time stamps as the product passed through different manufacturing stages. The images as well as these features were then used for training of algorithm. The output of the model is binary where “1” represented that the product has no faults and “0” represents that it is defective.

We use deep learning based computer vision technology for the development of the system. With the usage of deep learning, the goal is to minimize human intervention and achieve human like accuracy.

We extract features from the data collected in the first step using Convolutional Neural Networks (CNNs). CNNs look for patterns in the images. The first layers of the CNNs, regular features like lines/curves and edges can be detected. As we go deeper into a CNN network, more complex features are extracted which are vital to detect and classify the defective products.

For predictive quality, we used Long Short Term Memory Networks (LSTMs). LTSMs are special type of Recurrent Neural Networks (RNNs) which are capable for learning long term dependencies . LSTMs use gated cell to contain information outside the flow of RNN. Much like memory in a computer, data can be written to and read from this memory cell. Decisions like what to store and when to allow the read operations are taken by the cell itself. These storage cells are analogue in nature unlike the storage on a computer. They are implemented by element wise multiplication of sigmoids and their analogue nature make them suitable for backpropagation.

The data that we were dealing with was time series data and unlike predictive modelling using regression, time series data also has added complexity of sequence dependence. LSTMs are very effective to model problems having multiple variables. They also offer a lot of flexibility in terms of parameter control and tuning. Several combinations of LSTMs can be used to forecast time series (one to many, many to many etc) . There are also many customization options when working with LSTMs. Remembering information for long term is the default behaviour of LTSMs and this is why they are so helpful in solving the time series prediction problems.

We train the CNN model with thousands of images of the product and let it learn the different types of defects from the data itself. Once the training process is complete, it’s time to deploy the model.

Once the model has been trained with extensive dataset, we deploy the model. This step means having the model be accessible to anyone who can use it to see or measure or calculate something. We use “” for rapid sharing and testing of the model.

Analytics Tool Integrated with Manufacturing

Finally, the AI system is integrated with Analytics Dashboard that gives you insights about different types of defects that have been encountered in the process. So with the system, you not only detect the defects but also analyze the most frequent defects that occur in the production. This information can be used by production line operators to optimize the variables responsible for these defects. We have also built a micro service which can be integrated to your already existing system.

Results

Integrating the goodness of the automatic inspection system into your business As you have seen, our system comes to the rescue of saving you all the trouble of manual inspection of your manufacturing products. With this system

- You do not need to have dedicated specialist team needed for quality control

- The efficient deep learning based model reduces the production of defective products by 15%

- A great analytics tool gives you insights about most frequent defects and when things are likely to go wrong.It also helps you find out root cause of the defects and lets you take actions to cope with those